Vex3m: Revolutionizing Precision in 3D Printing with Advanced Material Handling

Vex3m: Revolutionizing Precision in 3D Printing with Advanced Material Handling

In the fast-evolving world of industrial 3D printing, innovation hinges on material versatility and print accuracy. Vex3m has emerged as a trailblazer, introducing a breakthrough system designed to optimize print precision by mastering complex material behaviors and adaptive process control. Drawing on cutting-edge sensor integration, real-time feedback loops, and AI-driven diagnostics, Vex3m enables manufacturers to push the boundaries of what’s possible in additive manufacturing.

This article explores how Vex3m redefines material handling and print quality, transforming production workflows across industries.

Engineered for Material Intelligence

At the core of Vex3m’s success is its intelligent material response system, engineered to handle diverse and demanding materials—from high-performance polymers and composites to reactive metals and thermosets. Unlike conventional 3D printers that apply fixed parameters, Vex3m dynamically adjusts extrusion rates, temperature profiles, and layer adhesion settings based on live material feedback. “Traditional systems treat materials as static inputs,” explains Dr.

Elena Marquez, a materials engineer and Vex3m project lead. “Vex3m sees variations in viscosity, thermal expansion, and curing behavior—and responds at sub-second intervals to maintain consistency.”

This adaptive capability is powered by embedded sensors monitoring: - Real-time temperature gradients across the build chamber - Flow rate consistency in dual-extrusion setups - Curing speed and chemical reaction kinetics for resin-based prints - Mechanical stress buildup during layer deposition

Data from these sensors feeds into a proprietary control algorithm that fine-tunes print parameters in real time. The result is a dramatic reduction in defects—warping, delamination, and porosity—common in complex or multi-material prints.

Precision Calibration Through Dynamic Feedback Loops

Precision in 3D printing depends not only on hardware consistency but on continuous monitoring and adjustment.

Vex3m surpasses conventional closed-loop systems with a multi-layered feedback architecture that integrates machine learning and predictive analytics. “Most 3D printers rely on reactive corrections,” says technical director Marcus Lin. “Vex3m anticipates print deviations before they occur—using historical data and material-specific models to preempt errors.”

Key components of Vex3m’s feedback system include: - Closed-loop thermal management: PID controllers regulate heater and cooling units with microsecond accuracy to stabilize thermal zones - Layer-by-layer photometric analysis: High-resolution cameras and spectrometers verify cure depth and interface integrity - Stress and deformation mapping: Strain gauges embedded in the build plate detect internal stresses and trigger adaptive path planning - AI-driven print profiling: Machine learning models trained on thousands of print jobs optimize paths and supports for each unique geometry and material combination

This integration of feedback mechanisms enables Vex3m to maintain dimensional accuracy within ±0.05mm across large-format prints—critical for aerospace components, medical implants, and custom tooling where tolerances dictate functionality and safety.

Expanding Material Frontiers with Vex3m’s Adaptive Technology

One of Vex3m’s most transformative attributes is its ability to process a broad spectrum of advanced materials, each with distinct physical and chemical properties.

Traditional additive systems often struggle with multi-material prints due to incompatibility in melting points, curing times, or adhesion characteristics. Vex3m overcomes these limitations through its intelligent material switching and blending capabilities.

Materials consistently supported by Vex3m include: - High-temperature thermoplastics like PEEK and ULTEM, critical for aerospace applications - Conductive composites infused with carbon nanotubes or graphene for electronics integration - Biocompatible resins used in dental and orthopedic printing - Photopolymers with tailored elasticity for flexible wearables - Reactive metal alloys compatible with binder jetting and directed energy deposition

Vex3m’s adaptive extrusion system ensures seamless transitions between materials, avoiding nozzle clogging or thermal shock.

A unique “smart bridging” function preserves inter-layer adhesion when switching from rigid to ductile materials, preventing delamination. For resin-based builds, dynamic UV intensity and exposure scheduling adjust per layer to accommodate varying penetration depths.

This versatility empowers engineers to merge function and form in unprecedented ways—fabricating complex, multi-material prototypes and end-use parts in a single build cycle, eliminating assembly steps and reducing time-to-market.

Real-World Applications: From Prototyping to Mass Production

Vex3m’s impact resonates across industries where precision, material efficiency, and repeatability are paramount.

In aerospace, manufacturers use Vex3m to print lightweight, high-strength structural components with internal lattice geometries that reduce weight without compromising strength. Sensors integrated during printing generate real-time quality reports, enabling regulatory compliance for certified parts.

Medtech companies leverage Vex3m’s biocompatible material handling to produce patient-specific implants—crowns, joint replacements, and surgical guides—with surface finishes meeting medical-grade standards.

The system’s contamination controls and sterile processing environments ensure biocompatibility and infection resistance.

In automotive development, Vex3m accelerates prototyping of complex under-hood components and aerodynamic parts, where thermal and mechanical durability are critical. Rapid iteration with precise material allocation cuts development costs and shortens product cycles.

Custom manufacturing and artisanal producers also benefit from Vex3m’s scalability. One art studio recently used the system to print a full-scale, functionally integrated sculpture embedded with embedded conductivity, demonstrating Vex3m’s capacity to merge artistry with engineering precision.

The Future of Precision Additive Manufacturing

Vex3m stands as a benchmark in the evolution of industrial 3D printing—where material intelligence meets dynamic control to deliver unmatched consistency and flexibility. By integrating advanced sensors, AI-driven feedback, and adaptive process logic, the platform transforms additive manufacturing from a niche prototyping tool into a robust, scalable production technology.

“We’re not just printing parts—we’re engineering certainty,” notes Lin. “Every layer saved from warping, every defect preempted, every material optimized ensures that when Vex3m prints, it’s truly delivering on its promise.”

As industries demand higher precision, faster turnaround, and broader material access, Vex3m continues to redefine the limits of what is feasible in 3D printing. Its impact extends beyond technical performance—driving sustainability through material efficiency, reducing waste, and accelerating innovation across manufacturing frontiers.

With Vex3m, the future of additive manufacturing is no longer a vision—it’s a new reality.

Related Post

Military Might Meets Strategy: Top War Mods Transforming Minecraft Bedrock Edition’s Battlefields

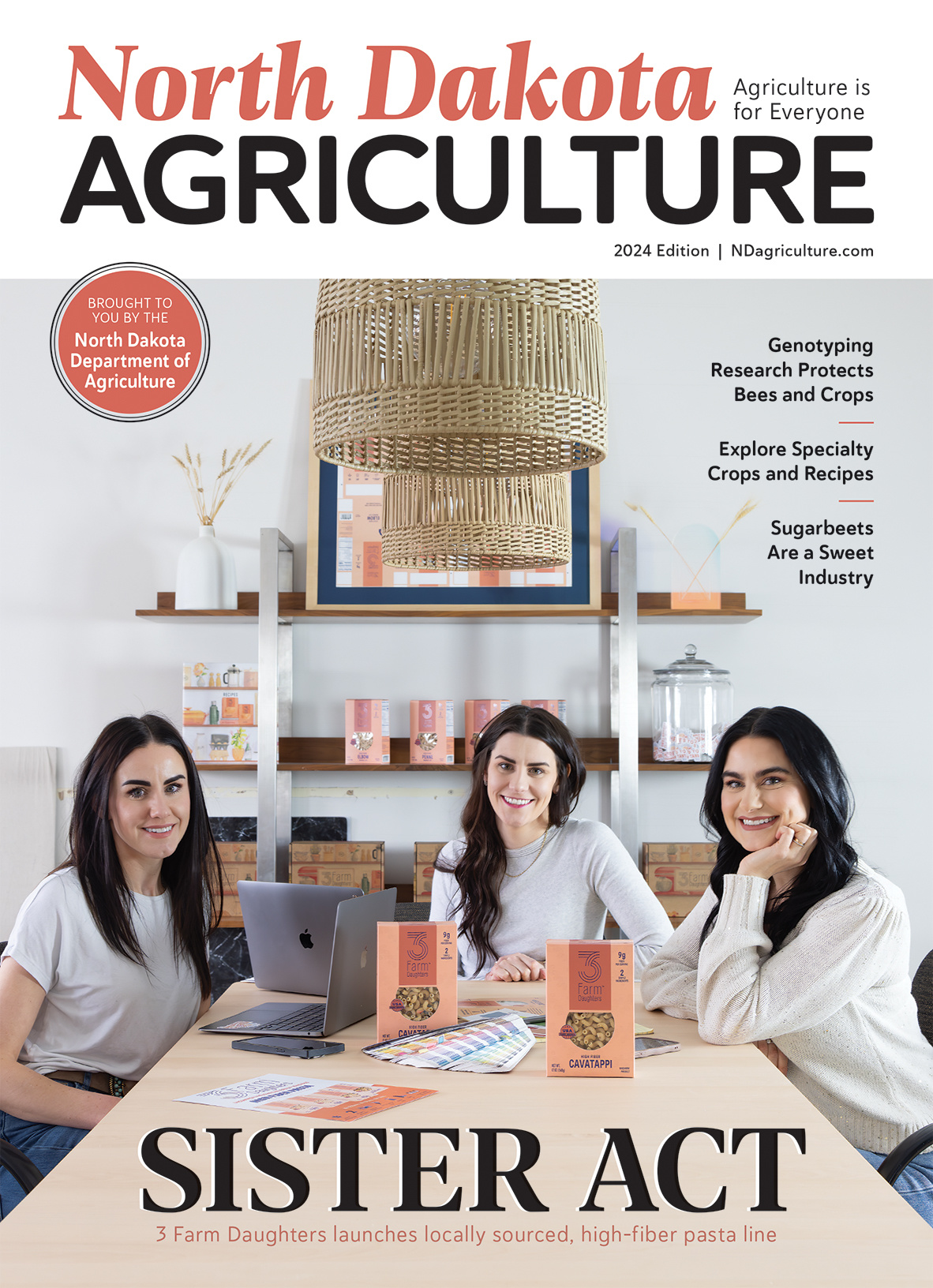

North Dakota Agriculture Grants: Powering Farm Growth with Strategic Funding

The Role of Prince Rupert, Canada: Gateway to the Pacific and Hub of Strategic Innovation

State Farm Pay Bill A Simple Guide: Master Your Automatic Payments with Confidence