The Unstoppable Force of TNT: Unlocking the Power Behind the World’s Most Potent Explosive

The Unstoppable Force of TNT: Unlocking the Power Behind the World’s Most Potent Explosive

TNT—trinitrotoluene—stands as one of history’s most iconic and influential high explosives, blending raw power with operational versatility. Since its synthesis in the late 19th century, TNT has become the benchmark for military, industrial, and scientific applications, defining speed, precision, and reliability in explosive technology. From battlefield dominance to precision manufacturing, its unique properties continue to shape modern engineering and defense strategy.

The Scientific Backbone of TNT’s Power

At its core, TNT’s explosive strength stems from a stable molecular structure rich in nitro groups—three of which bond to a toluene ring.

This configuration, C7H5N3O6, gives TNT a detonation velocity of approximately 8,600 meters per second—among the fastest for chemical explosives. Unlike many high explosives that rely on complex tetrazole or nitroamine chemistry, TNT’s simplicity enhances stability, making it less prone to accidental detonation while maintaining superior performance. Key performance metrics: - Detonation velocity: 8,600 m/s - Detonation pressure: ~6.0 GPa (6,000 atmospheres) - Heat of explosion: ~5,200 kJ/kg (among the highest for organic explosives)

This explosive efficiency enables rapid energy release, ideal for applications demanding precision and force.

Its heat of combustion translates directly into forceful blasts, driving projectile speeds in artillery and shaping craters in military ordnance. The thermal stability of TNT’s decomposition products further ensures consistent performance across wide temperature ranges, a critical edge in variable field conditions.

From Battlefield Dominance to Industrial Precision

TNT’s military legacy is unmatched. Adopted widely by global forces during World War I and II, it became the backbone of artillery shells, grenades, and fuses, known for balanced power and manageable handling.

Its reliability under fire earned it a reputation as the “standardapiêtape” of explosive ordnance, setting benchmarks later surpassed only by more specialized compounds like C-4.

Beyond defense, TNT revolutionized industrial engineering. Its clean burn and predictable fragmentation make it a prime choice for controlled demolition, including controlled blasts in mining, tunneling, and infrastructure projects.

Unlike metal-based explosives that leave debris or corrode machinery, TNT’s residue is primarily inert byproducts—primarily toluene, nitro compounds, and carbon—reducing post-operation contamination and maintenance costs.

Despite older origins, TNT remains a staple in global explosives production, though manufacturing has evolved toward safer, scalable methods. Historical production relied on batch hydrolysis and distillation, but modern facilities now use continuous chemical synthesis with advanced process controls to ensure purity and safety. Strict international regulations govern its production and distribution, mitigating illicit trafficking while supporting legitimate military and industrial needs. Customization defines TNT’s contemporary use. Engineers tailor its form—cash pellets, ingots, or bonded composites—to serve specialized roles: - **Cash pellets:** Small, dense units for proximity fuses and tracer rounds, offering precise detonation timing. - **Ingot form:** Used in larger charges for controlled demolitions requiring calibrated blasts. - **Bonded TNT:** Mixed with polymers or cement for seismic monitoring or blast-resistant construction, enhancing stability and energy transmission. These adaptations illustrate TNT’s versatility, proving it remains relevant beyond legacy systems despite newer composites like HMX. The global demand for reliable, cost-effective high explosives ensures TNT’s continued centrality in both defense logistics and technical innovation. Handling TNT demands strict safety protocols. Though less sensitive than some explosives, improper storage—such as exposure to heat, shock, or incompatible materials—can trigger dangerous autoignition. Modern facilities enforce rigorous protocols: secure storage in cool, dry environments, regular structural inspections, and specialized hazmat teams trained in emergency response. Environmental considerations shape current practices. TNT’s byproducts, while less toxic than alternatives like PETN or C-4, still require careful management. Modern municipal waste programs now include specialized incineration or chemical neutralization to prevent soilSupply Chains, Manufacturing, and Modern Adaptation

Safety, Environmental Impact, and Responsible Stewardship

/origin-imgresizer.tntsports.io/2025/10/23/image-a0103ff9-e841-4c47-b98b-59da27499d92-68-310-310.jpeg)

Related Post

The Ultimate Guide to Crafting TNT in Minecraft: A Blast of Infinite Power

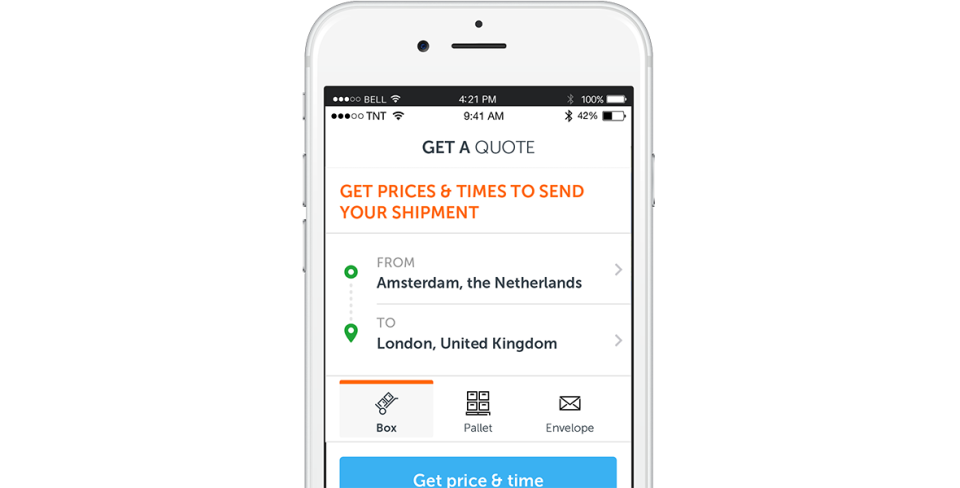

TNT Live: Revolutionizing Live Entertainment with Infinite Precision and Immersive Power

Stream TNT: Revolutionizing Real-Time Data Streams with Unmatched Precision

Build Your Bedrock TNT Launcher in Minecraft with Zero Effort – The Easy Guide