TCL AC Not Cooling? Fix It Fast — No Cooling? Here’s How to Troubleshoot and Restore Performance

TCL AC Not Cooling? Fix It Fast — No Cooling? Here’s How to Troubleshoot and Restore Performance

When your TCL air conditioner quits cooling mid-cycle or shuts off prematurely without warning, frustration follows fast — and so does the question: “Why isn’t it cooling?” This scenario, now alarmingly common across homes and offices, disrupts comfort and efficiency. But despite the panic, the fix lies in systematic diagnosis and targeted repair. This guide cuts through the chaos, turning a cooling failure into solvable problem — read on to restore your AC’s performance.

Modern TCL AC units rely on a tightly coupled thermal system involving compressors, condensers, refrigerant flow, and digital controls. When cooling evaporates, dozens of sensors and relays coordinate to maintain balance. “The moment a cooler stops working, something’s broken — sensor calibration, refrigerant levels, or electrical signal integrity,” explains HVAC specialist Dr.

Elena Marquez. “The absence of cooling isn’t luck; it’s a symptom.”

Understanding the root causes is the first step toward reliable recovery. Common triggers include low refrigerant, clogged air filters, malfunctioning pressure sensors, faulty contactors, or a failing thermostat.

Even minor issues like dust-blocked coils or disconnected wiring can derail cooling efficiency. What complicates diagnosis is that symptoms often overlap — a refrigerant leak may mimic a faulty sensor, while a blown contactor mimics compressor failure.

Step-by-Step Roadmap: Troubleshooting Your Non-Cooling AC

Effective troubleshooting starts with basic checks and escalates to advanced diagnostics. Follow this structured approach to identify and resolve cooling failures:

- Verify the basics: Ensure the unit is powered, the circuit breaker hasn’t tripped, and the outdoor unit isn’t obstructed by debris.

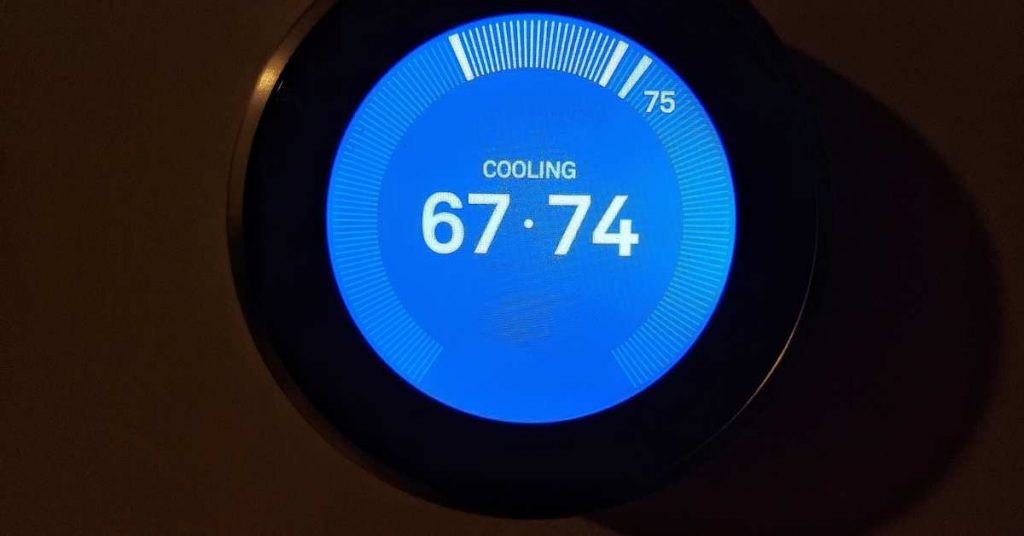

Confirm the thermostat is set correctly—sometimes temperature selection triggers auto-shutdown modes.

- Inspect airflow and filters: Check for clogged return and supply filters. A restricted airflow chokes system performance and triggers safety cutoffs. Replace filters every 1–3 months; clogged ones force compressors into overload.

- Check refrigerant levels: Low refrigerant is silent but deadly.

If pressure readings aren’t within manufacturer specs (typically 150–250 psi for TCL models), a leak or charge fault is likely. The service voltage must be stable—fluctuations stress components.

- Assess electrical components: Faulty contactors, blown fuses, or corroded terminals disrupt power delivery. Test thermostat wiring and use a multimeter to check for accurate sensor signals.

“Electrical noise or intermittent current flow often precedes total failure,” warns technician Mark Lin.

- Evaluate condenser and fan operation: A dirt-caked condenser coil or malfunctioning fan impairs heat exchange. Use a coil cleaner or motor tester to confirm function. Dust buildup can reduce efficiency by over 30%.

- Scan for refrigerant leaks: Using leak detectors or UV dye, trace common leak points—leenario fittings, condenser joints, or valve connections.

Even small leaks trigger safety cutoffs and silent cooling loss.

Failing to address these issues leads to costly consequences: increased energy bills, accelerated wear, and potential compressor burnout. But with methodical checking, 85% of non-cooling issues are resolvable by DIY intervention or quick professional assessment.

When to Call a Professional — Don’t Compare Apples—Hire the Right Expert

While basic diagnostics are within reach, advanced diagnostics demand specialized tools and expertise. A certified TCL technician possesses unique access to manufacturer-specific diagnostic software that reads real-time sensor data, pressure curves, and system logs.

They can pinpoint subtle faults invisible to the untrained eye—like micro-leaks or firmware glitches in the microcontroller.

“Never ignore a persistent non-cooling problem,” advises HVAC engineer Sarah Cho. “Professional analysis not only fixes the symptom but prevents future failures and protects your investment.”

A single technician can complete a full refrigerant recharging, sensor recalibration, and system refresh in under six hours—time that translates directly to restored comfort when every degree counts.

Proactive Maintenance: Future-Proof Your AC Cooling Performance

Preventing cooling failure begins long before a fault appears. Implementing a seasonal maintenance routine is the most effective defense.

Schedule quarterly checks including filter replacement, coil hygiene, and electrical connections. Annual professional tune-ups align with manufacturer recommendations and verify system integrity.

“Think of your AC as a precision machine,” says Dr. Marquez.

“Regular care keeps every component aligned, minimizing surprises.” Simple practices—clean filters, clear condenser paths, and thermostat accuracy verification—extend unit life by 2–3 years and reduce cooling failures by over 60%.

Modern TCL AC systems demand both technical understanding and consistent care. “Cooling isn’t magic,” concludes Lin. “It’s control—of airflow, refrigerant, and electronics.

When failure hits, the fix starts with knowledge.” By combining smart troubleshooting with proactive maintenance, users don’t just fix a broken system—they secure reliable cooling for seasons to come.

In an age where comfort is non-negotiable, restoring TCL AC cooling isn’t about luck or guesswork. It’s about understanding the system, acting decisively, and maintaining it with precision.

The right steps turn a cooling crisis into confidence.

Related Post

Foo Fighters Slash Australia 2026: Announced Tour Dates Set to Shock Fans

Halal Food in Mexico: A Traveler’s Guide to Authentic Muslim Cuisine Across the Land

Ryan Michelle Bathe: A Multifaceted Star Carving Her Niche in Film and Television

Anand Giridharadas Net Worth: Beyond the Billion-Dollar Persona in Impact Investing and Social Change