Revolutionizing Precision: The Sinclair Bok Download and Core Electronics Manufacturing Processes Shaping the Industry

Revolutionizing Precision: The Sinclair Bok Download and Core Electronics Manufacturing Processes Shaping the Industry

In the intricate world of electronics manufacturing, precision and innovation converge to define what becomes state-of-the-art. At the heart of modern production lies the Sinclair Bok Download—a pivotal methodology that streamlines design, documentation, and fabrication workflows, enabling manufacturers to produce complex electronic systems with unprecedented speed and accuracy. This article explores the essential manufacturing processes behind high-performance electronics, spotlighting how integrating the principles outlined in the Sinclair Bok Download enhances efficiency, traceability, and quality control across every stage—from initial blueprint to final deployment.

Electronics manufacturing today transcends mere assembly; it is a symphony of advanced processes, automation, and rigorous standards. The Sinclair Bok Download, though not a physical document but a digital framework, embodies best practices that guide engineers and production teams through every phase of fabrication. It emphasizes structured data exchange, version control, and scalable design integration—critical for industries where even microscopic defects can compromise device reliability.

The framework enables seamless collaboration between design, engineering, and production**.

Selecting the right manufacturing processes is non-negotiable.

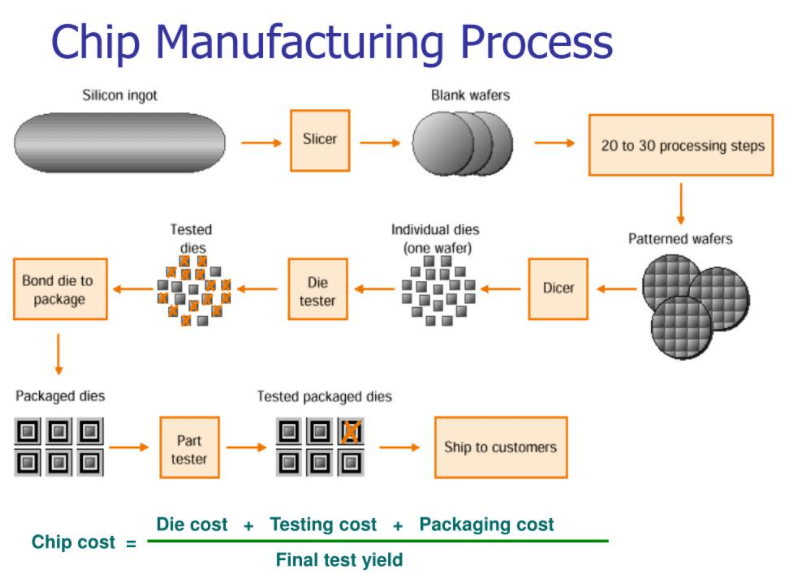

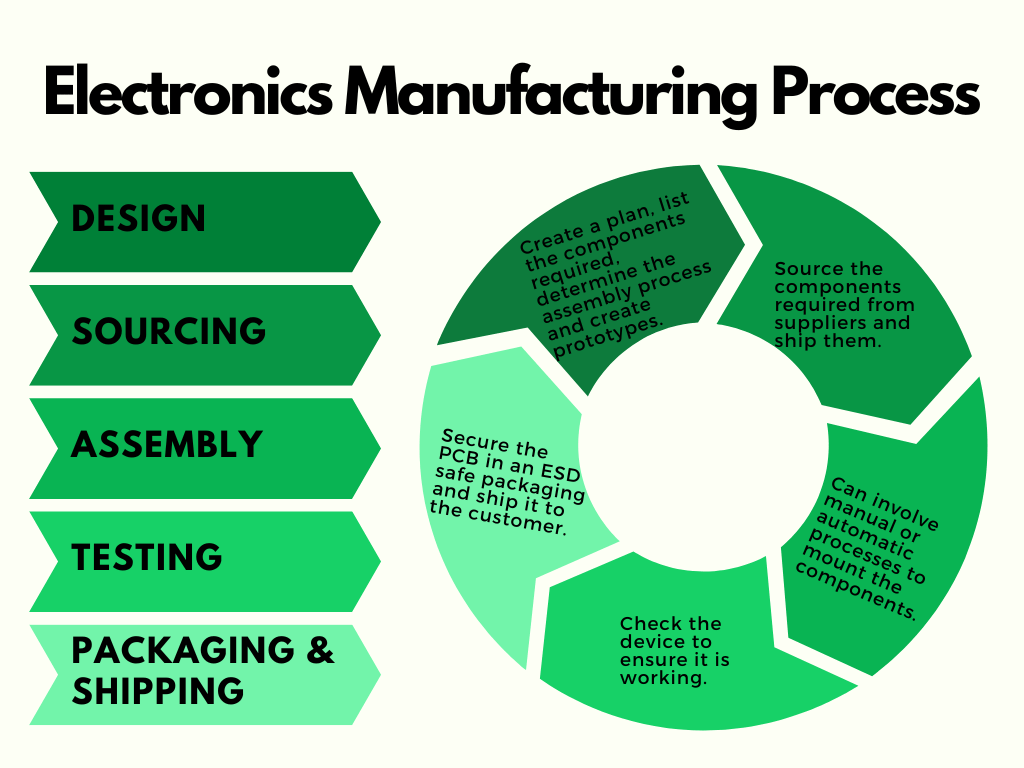

The journey from circuit concept to functional unit involves multiple stages, each demanding precision, traceability, and adaptability. Key processes include PCB fabrication, component assembly, reflow soldering, testing, and final integration—all of which must align with global quality benchmarks such as IPC-A-610 and ISO 9001.

These standardized methods ensure consistency, reduce variability, and support rapid iteration in fast-moving markets.

PCB Fabrication: The foundation of every electronic device begins with substrates meticulously patterned through photolithography and etching. Modern fabrication leverages advanced materials like high-frequency laminates and ceramic-based boards to meet performance demands in telecom, computing, and IoT applications.

Traceability starts here—every layer, trace width, and fid mark is digitally documented via the Sinclair Bok Download-inspired workflow, enabling full digital thread continuity.

Automated optical inspection (AOI) and laser drilling now achieve micron-level precision, reducing defects and rework.

Component Assembly: Bridging design and function transforms flat boards into active systems. Surface Mount Technology (SMT) dominates present-day manufacturing, allowing high-density component placement with micron accuracy. The Sinclair Bok Download methodology reinforces this stage by enforcing standardized datasheet validation, robotic pick-and-place protocols, and real-time inventory tracking.

Vision-guided systems inspect each solder joint, flagging voids, cold joints, or misalignments before components proceed to inspection.

This digital-physical convergence ensures that every device meets stringent reliability criteria under thermal, mechanical, and electrical stress.

Reflow Soldering: Precision in thermal bonding remains a cornerstone of assembly integrity. Using controlled temperature profiles, reflow ovens bake PCBs at precisely programmed rates—melting solder paste without damaging sensitive components. Modern reflow systems incorporate infrared sensing and dynamic fan curves to maintain uniform heat distribution, minimizing warping and overheating risks.

Data from each reflow run is logged into centralized manufacturing databases, feeding quality metrics and enabling predictive maintenance.

These automated, monitored processes drastically improve yield and reduce production downtime.

Functional and Environmental Testing: Validate before deployment lies at the heart of reliability assurance. A bid, typically performed through Automatic Test Equipment (ATE), applies electrical, functional, and environmental stress tests to verify performance across temperature, humidity, and vibration extremes. Newer sytems integrate real-time analytics and AI pattern recognition to detect subtle anomalies invisible to traditional methods.

Defective units are pinpointed and quarantined, ensuring only high-integrity units enter distribution.

This rigorous testing, aligned with design specifications from the design phase via the Sinclair Bok framework, guarantees products meet or exceed client expectations.

Quality control pulses through every layer of electronics manufacturing. From vendor qualification to inline inspection and final certification, each touchpoint is governed by traceability standards. Automated systems cross-reference manufacturing execution data with design intent, flagging deviations the moment they occur.

This digital thread enhances compliance, supports rapid root-cause analysis, and ensures full auditability—a critical advantage in regulated industries like medical devices and aerospace.

Data synchronization between ERP, MES, and quality systems strengthens these controls.

The Sinclair Bok Download externally bridges design documentation and manufacturing execution, but its principles echo deep within the machinery of modern electronics production. By embedding rigorous process discipline across PCB fabrication, SMT, reflow, and testing, manufacturers achieve faster time-to-market, reduced scrap, and superior product consistency. As electronics evolve toward miniaturization, higher speeds, and greater complexity, these integrated approaches become indispensable.

They turn vast technical complexity into repeatable, scalable operations.

Real-world examples abound: semiconductor foundries using Sinclair-aligned workflows report 30% lower defect rates; IoT device makers achieve certified compliance in record time through automated documentation and process validation; and aerospace electronics manufacturers leverage multi-stage verification to exceed MIL-STD-883 standards.

These results speak to a broader transformation—one where structured manufacturing processes, inspired by digital documentation best practices, drive innovation forward.

Efficiency meets excellence at scale.

The ongoing evolution of electronics manufacturing hinges on harmonizing cutting-edge technology with disciplined processes. The Sinclair Bok Download serves as a blueprint, not just for documentation, but for cultivating a culture of precision and continuous improvement. As global demand surges for smarter, smaller, and more reliable devices, manufacturers who adopt these integrated, data-driven approaches position themselves at the forefront of industry leadership.

In a world defined by connectivity and complexity, mastering these manufacturing processes is no longer optional—it’s essential.

Related Post

Unblocking the Battle: Mastering 1v1 Lol Unblocked 66 in a Walled Digital Arena

Goldie Hawn’s Fortune: Decoding the Financial Empire Behind the Icon’s Market Realist Legacy

Unveiling the Controversy: The Pokimane Deepfake Phenomenon

Alycia Parks: Architect of Brand Excellence and Cultural Influence