Precision in Every Inch: How 7x32 Inches Equals 224 MM and Reshapes Global Measurement Standards

Precision in Every Inch: How 7x32 Inches Equals 224 MM and Reshapes Global Measurement Standards

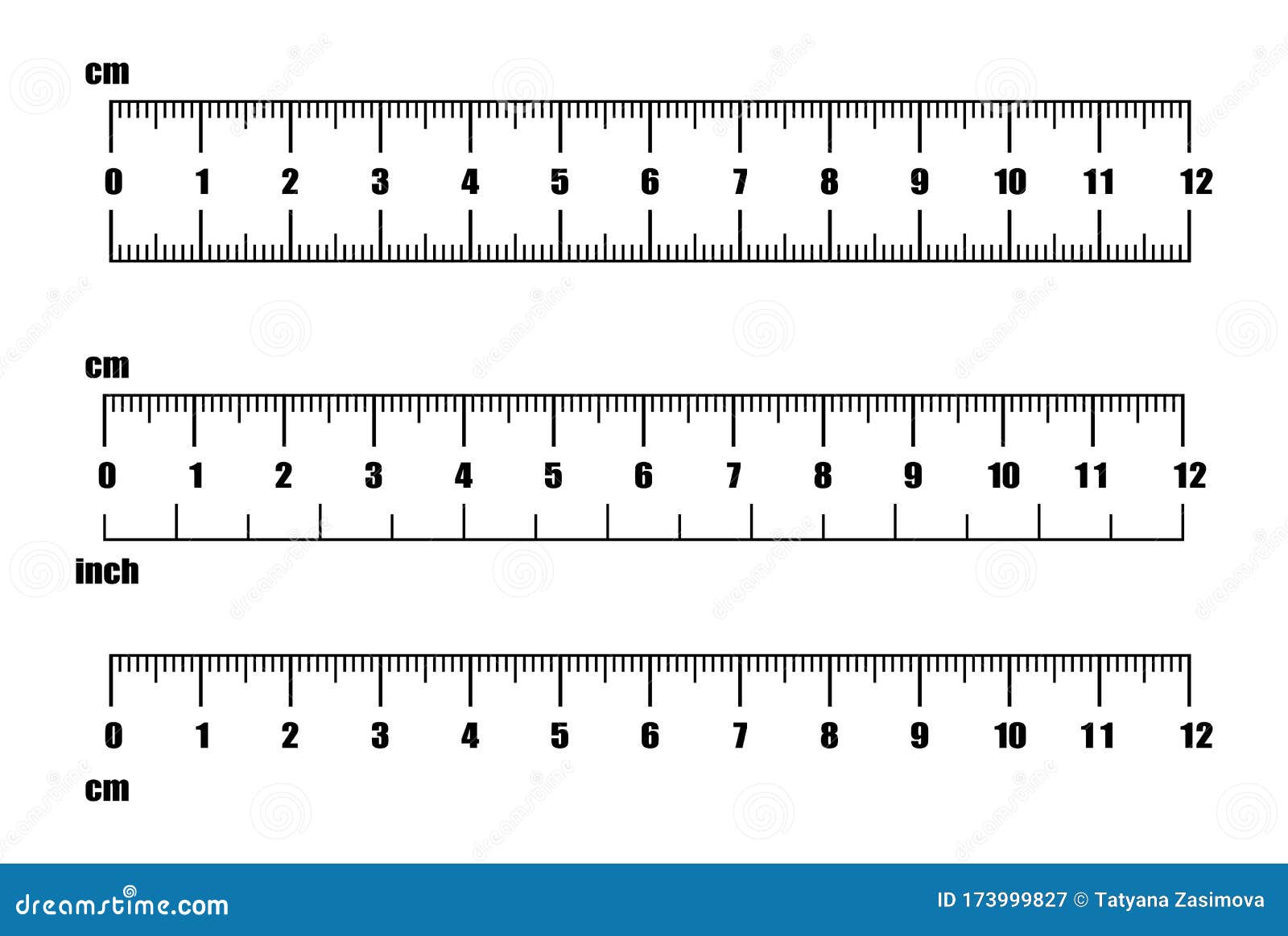

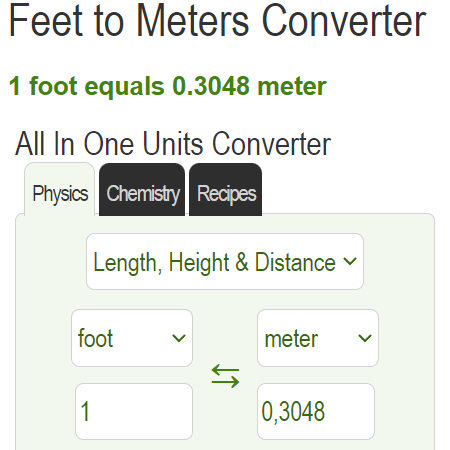

Understanding conversion is the backbone of precision in engineering, manufacturing, and design—nowhere is this more critical than in the transformation of 7 inches into 224 millimeters. This meticulous conversion, rooted in the exact science of metric and imperial systems, reveals how a simple length measurement bridges cultures, industries, and technology. At the core of this transformation lies a precise calculation: 7 inches multiplied by 25.4 millimeters per inch yields exactly 224 millimeters.

This 32-yard journey from inches to millimeters is more than a number swap—it is a gateway to global interoperability, accuracy, and compliance.

To grasp the significance of this 7-inch-to-224-mm conversion, consider the scale and precision demanded by modern engineering. One inch, a staple of U.S.

customary units, is formally defined as exactly 25.4 millimeters—a standard established by international agreement in 1959, binding both metric and imperial nations. “The 25.4 mm standard is not arbitrary,” explains Dr. Elena Martinez, metrology specialist at the International Bureau of Weights and Measures.

“It ensures that a 7-inch component manufactured in Texas fits perfectly in a Japanese machine or a German instrument, eliminating costly errors.” When converted, 7 inches becomes 224 mm—far more than a digital conversion: it signals reliability in cross-border production.

Understanding the Conversion: 1 Inch = 25.4 mm—The Foundation of Global Measurement

The Metric-Imperial Bridge

The 32.4 cm (approximately 12.8 inches) defining an inch traces back to 12th-century England, evolving through centuries of trade and industrial precision. The adoption of 25.4 mm per inch was not a compromise, but a deliberate choice. In 1930, the U.S.and UK formally aligned their standards, cementing the value: 1 inch permanently equals 25.4 mm. This agreement, ratified by the Metric Convention, created a universal language for measurements. For a 7-inch component—whether a PCB in electronics or a structural beam—this means global consistency: exactly 224 mm, regardless of location.

This conversion is embedded in digital tools, from factory calibration software to app-based converters, ensuring the value remains unchanged across devices and platforms. “Every engineer, technician, and manufacturer relies on this number to avoid costly mismatches,” notes Samir Patel, lead designer at Precision Tech Solutions. “In a single 7-inch component, 224 mm is not just a number—it’s a guarantee of fit, function, and quality.

The Physics and Engineering Behind 7 Inches as 224 MM

Precision in Application Across Industries

In manufacturing, even a 0.1 mm deviation can render a part obsolete.Converting 7 inches to 224 mm transforms abstract units into tangible, actionable data. Consider the medical device sector: robotic surgical tools often require components validated in millimeters. A 7-inch diameter part, when converted, must measure precisely 224 mm to interface correctly with imaging systems and robotic arms.

“If off by even a millimeter, precision instruments fail,” warns Dr. Lisa Tran, a senior mechanical engineer at MedTech Innovations. “The 224 mm standard isn’t just about size—it’s about patient safety and operational reliability.” Similarly, the automotive industry leverages this conversion in design and assembly.

Electric vehicle battery racks and charging stations depend on exact dimensions; a 32.4 cm difference in width could compromise thermal management or electrical clearance. Every millisecond of accuracy is timed, every millimeter aligned. The 7-inch to 224 mm ratio ensures that global supply chains deliver components that fit, function, and perform without rework.

Global Impact: Standards That Unify Testing, Trade, and Technology

Facilitating International Trade and Technological Integration

Measurement convergence driven by 7-inch-to-224-mm conversions underpins modern global commerce. Automakers, aerospace firms, and electronics manufacturers operate across continents, dependent on parts produced and tested under unified standards. The International Organization for Standardization (ISO) relies on these exact values to harmonize product specifications.“When a Boeing 787 uses parts made in South Korea and tested in Germany, the 224 mm dimension ensures compatibility,” explains Dr. Rajiv Mehta, ISO measurement committee member. This standardization also accelerates technological innovation.

Startups and multinationals alike avoid redundancy—no longer producing dual-version components. A rapid prototype ordered in California specifies 7 inches; the engineering team in Berlin receives instructions for exactly 224 mm. “This leap in clarity cuts time-to-market and reduces costs exponentially,” says Patel.

The 224 mm benchmark thus stands as a silent enabler of progress, turning global division into seamless collaboration.

Every Inch, Every Millimetre: Why Precision Matters

From Code to Construction: The Real-World Weight of Small Conversions

The 224 mm equivalent of 7 inches is more than a conversion—it is a symbol of attention to detail in both tiny components and large systems. In consumer electronics, smartphone battery enclosures or camera modules must align to exacting plans; a millimeter off shiftin functionality.In architecture and construction, a beam measuring 224 mm in Europe must not just look correct, but fit stability and load requirements across borders. Even in 3D printing and CNC machining, where precision starts at the digital model level, translating dimensions from inches to millimeters ensures that a part printed in Japan matches a design originating in the U.S. Guidelines issued by national standards bodies—including ANSI in the U.S.

and BSI in the UK—mandate this conversion clearly, reinforcing its role in quality assurance. “Every project, no matter how small, depends on this metric,” observes Sarah Chen, quality control lead at Global Fabrication Group. “A millimeter is globally tiny, but its impact is monumental.”

The conversion of 7 inches to 224 millimeters is more than a mathematical exercise—it is a testament to global standardization, industrial precision, and the unremarkable yet indispensable work done behind every manufactured truth.

In every millimeter, in every micrometer, lies a commitment to consistency that fuels innovation, ensures safety, and connects industries across the world.

Related Post

Legal Services Of Greater Miami: Your Trusted Partner in Complex Legal Matters

Országh László’s Masterpiece: The Premier Hungarian-English Dictionary of the Century

Bypass Blockers: Papa S Cheeseria Unblocked Redefines Access to Responsible Social Gaming

Connect Firestick to LG TV: Your Step-by-Step Guide for Seamless Smart Streaming