DPavkr: The Unseen Force Reshaping Modern Precision Engineering

DPavkr: The Unseen Force Reshaping Modern Precision Engineering

In a world driven by the relentless pursuit of accuracy and efficiency, DPavkr has emerged as a pivotal technology transforming engineering, manufacturing, and automation sectors. This advanced system, rooted in dynamic parameter control and adaptive feedback loops, enables real-time optimization of complex processes—ushering in unprecedented levels of performance and reliability. From semiconductor fabrication to aerospace component assembly, DPavkr is not just a tool but a foundational pillar of next-generation industrial innovation.

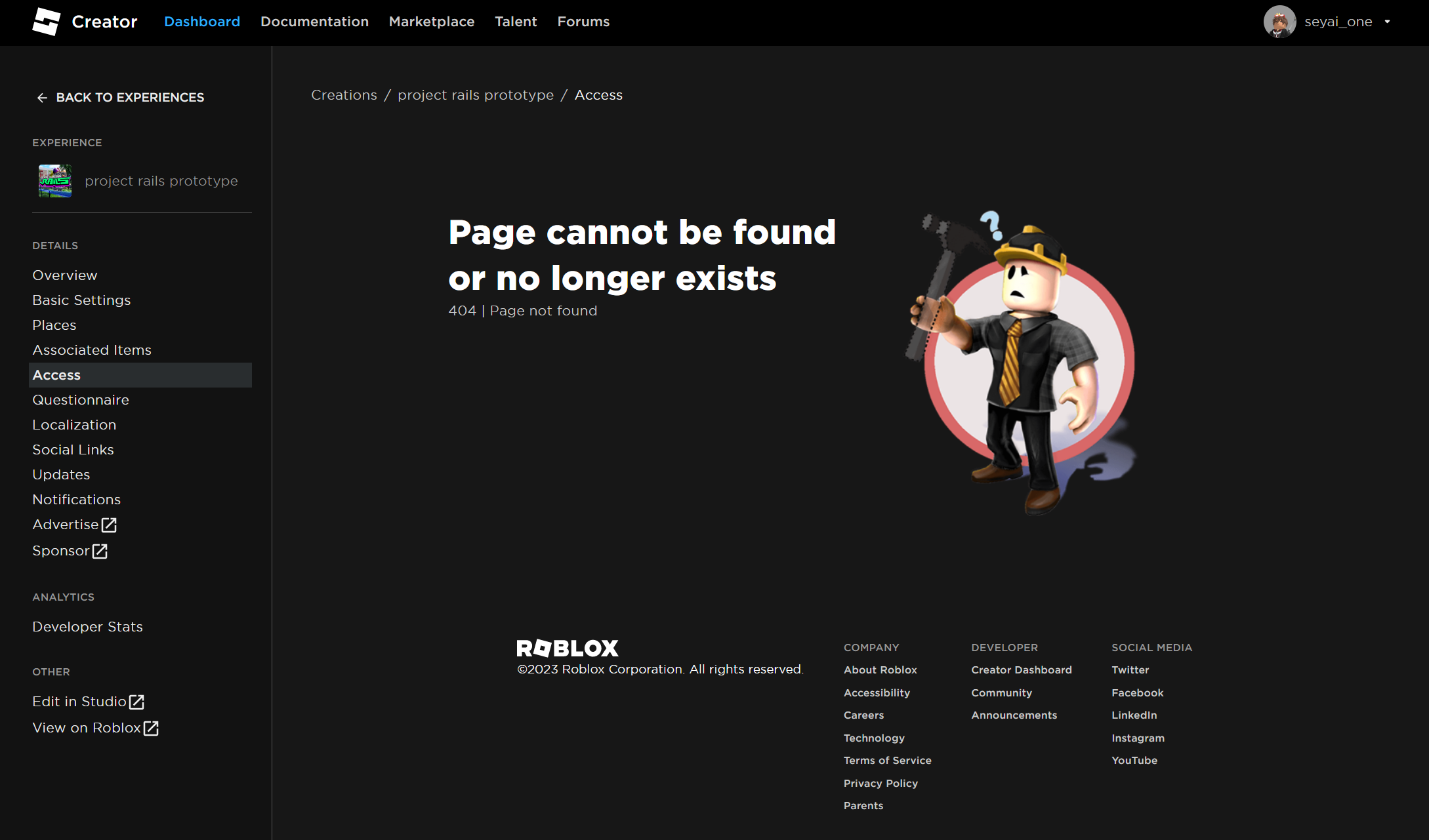

What Is DPavkr? Defining the Technology and Core Principles

DPavkr, short for Dynamic Parameter Adaptive Feedback Regulation, is a sophisticated control framework that leverages real-time data streams and machine learning to continuously adjust operational parameters. Unlike conventional static control systems, DPavkr dynamically responds to environmental fluctuations, machine wear, and input variability, ensuring consistent output quality and energy efficiency.At its core, DPavkr integrates five key components: - **Sensor Networks:** High-resolution sensors capture live operational data across multiple variables—temperature, pressure, speed, and alignment. - **Feedback Loops:** Continuous monitoring enables instant error correction, minimizing deviation from target performance. - **Predictive Algorithms:** Machine learning models forecast deviations and preemptively adjust settings before inefficiencies occur.

- **Adaptive Control Engine:** A modular processor recalibrates system parameters in real time, maintaining optimal performance across diverse workloads. - **User Dashboards:** Intuitive interfaces provide live insights, allowing engineers to monitor, analyze, and fine-tune system behavior. “DPavkr doesn’t merely react—it anticipates,” states Dr.

Elena Marquez, lead systems architect at Hybrid Dynamics Inc. “By merging real-time analytics with adaptive intelligence, it transforms reactive maintenance into proactive optimization.”

This capability marks a fundamental departure from traditional automation systems, which often rely on pre-programmed responses and fixed thresholds. With DPavkr, machines evolve alongside operational demands, reducing downtime and extending equipment lifespan through intelligent self-regulation.

Applications Across High-Stakes Industries

The versatility of DPavkr is evident in its widespread adoption across industries where precision dictates success. In semiconductor manufacturing, where nanometer-scale accuracy determines chip functionality, DPavkr maintains stable thermal and pressure conditions, reducing defect rates by up to 35% according to recent case studies. Automated welding systems in automotive assembly lines now leverage DPavkr to adapt to material thickness variations, improving joint consistency while cutting rework by nearly 20%.In aerospace, where component integrity under extreme stress is non-negotiable, DPavkr monitors turbine blade alignment and composite curing processes in real time. “Every degree and vibration is accounted for,” explains Dr. Rajiv Patel, systems engineer at SkyForge Innovations.

“DPavkr ensures that even under fluctuating flight loads, materials perform within exacting tolerances—critical for safety and longevity.”

Energy sectors also benefit significantly. DPavkr-powered grid management systems dynamically balance load distribution, integrating renewable sources with conventional power with minimal energy loss. This not only enhances grid resilience but supports decarbonization goals by optimizing consumption in real time.

Technical Architecture: How DPavkr Achieves Adaptive Mastery

DPavkr’s architecture represents a convergence of industrial automation, artificial intelligence, and control theory. The system operates across three concentric layers: - **Perception Layer:** A dense network of embedded sensors and IoT devices collects granular data from every stage of production. - **Analytics Layer:** Advanced algorithms process incoming streams, identifying patterns, anomalies, and causal relationships using deep learning and statistical modeling.- **Actuation Layer:** Precision actuators and servos implement adjustments within milliseconds, guided by predictive insights generated from the analytics layer.

What distinguishes DPavkr from earlier adaptive systems is its modular scalability and low-latency response. Unlike legacy adaptive controls that require extensive recalibration, DPavkr’s machine-learned models evolve autonomously through continuous feedback.

“The system doesn’t just follow rules,” notes Dr. Marquez. “It learns, adapts, and optimizes on a continuous cycle—much like a skilled human operator, but with greater consistency and speed.”

Interoperability is a cornerstone of DPavkr’s design.

It integrates seamlessly with existing SCADA systems, PLCs, and industrial IoT platforms via standardized protocol gateways. This plug-and-play capability accelerates deployment across legacy and next-gen facilities alike, reducing implementation barriers and enabling

Related Post

Defining Skinny: The Precision of Body Composition Beyond Size

Pinay Scandal News Latest Updates and Insights: Unpacking the Rising Turmoil in Filipino Public Spheres

How To Make Money Online: Mastering Skillshare Affiliate Strategies for Sustainable Earnings

Unlocking the Powerhouse: The I10 CPU and Its Dominant Role in Modern Computing